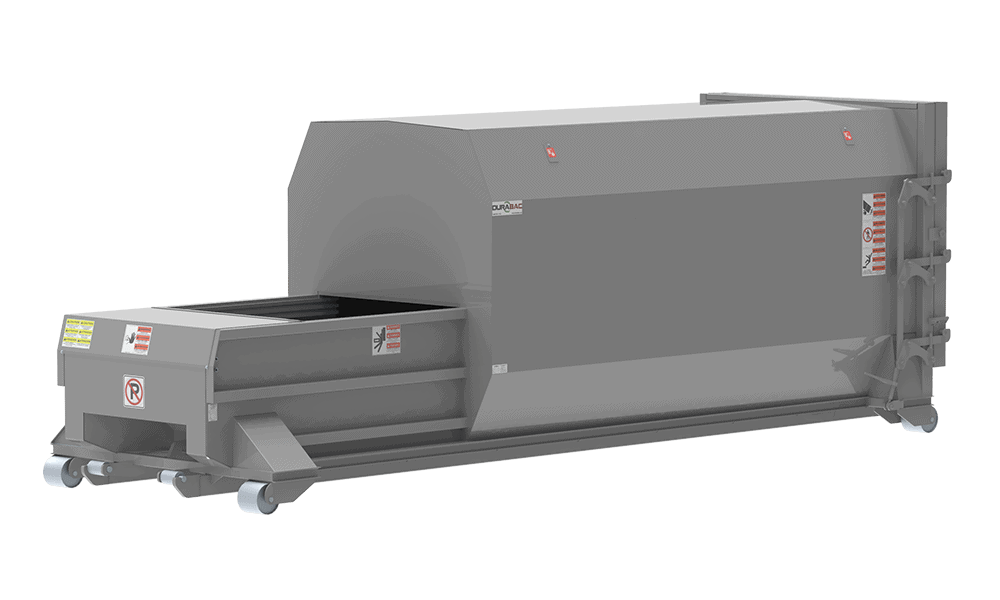

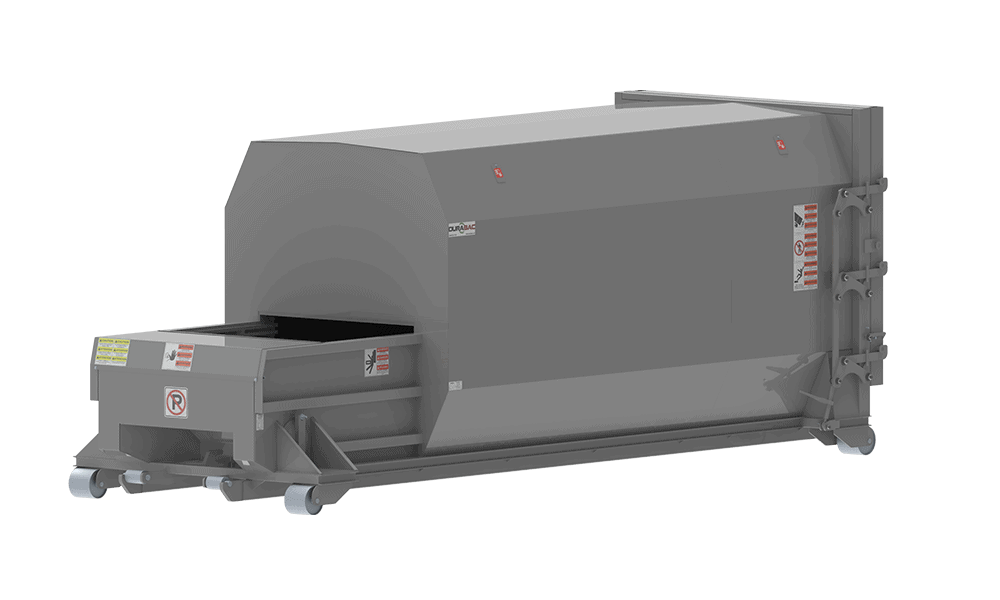

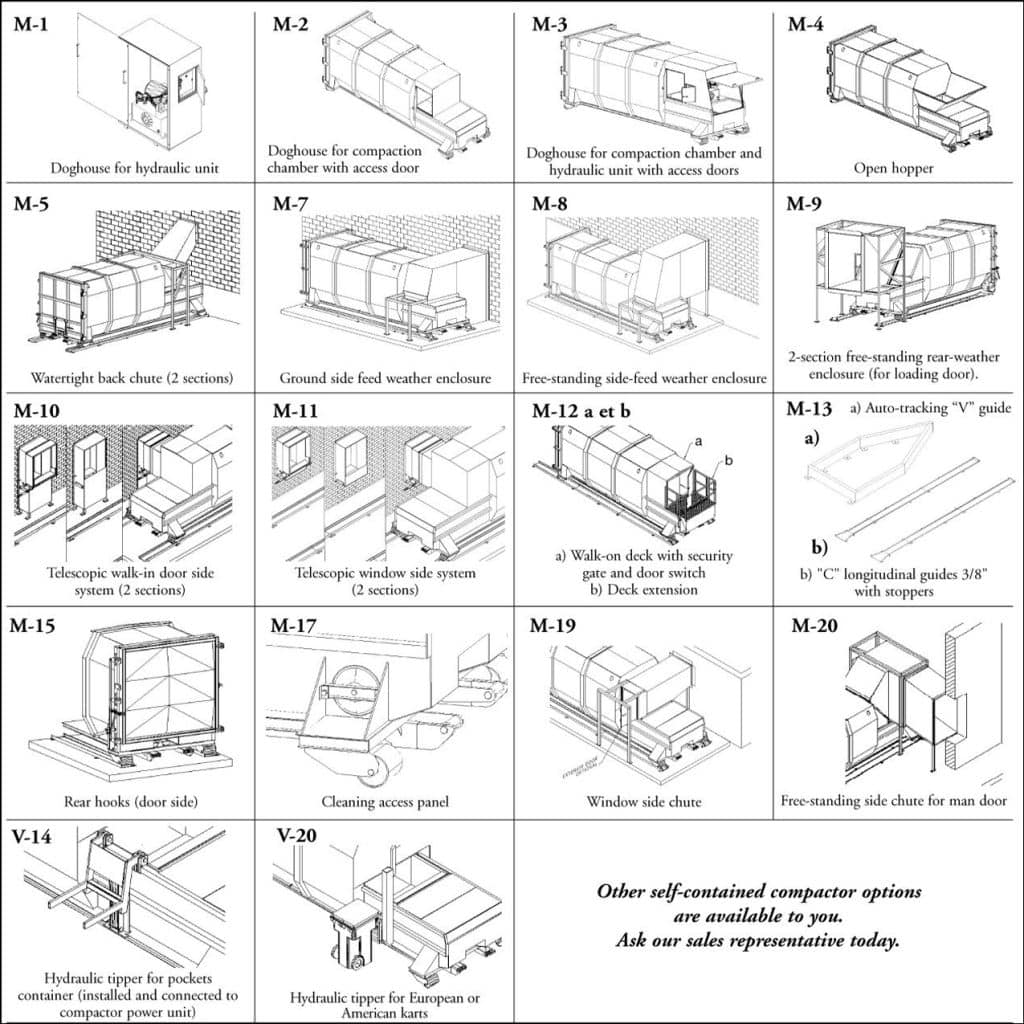

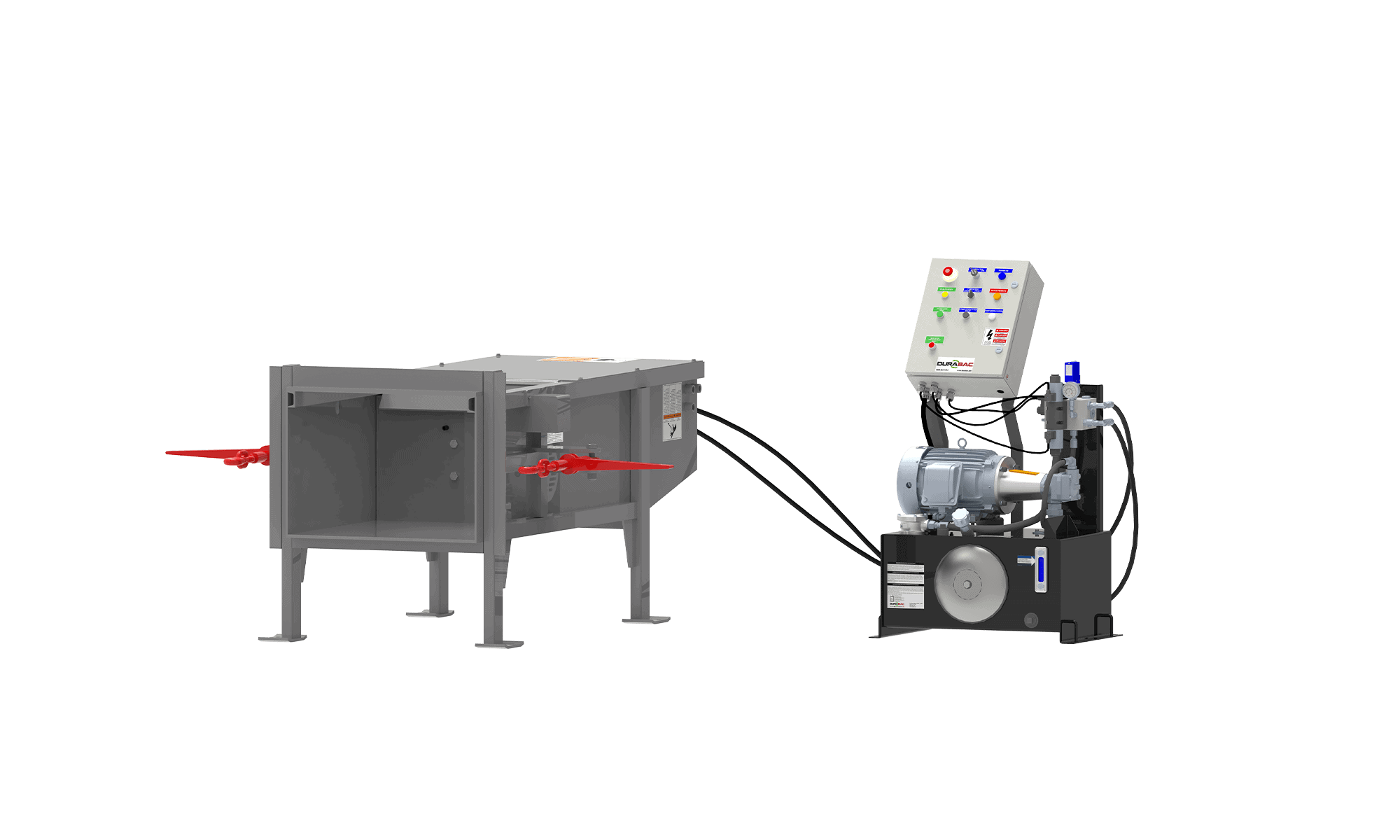

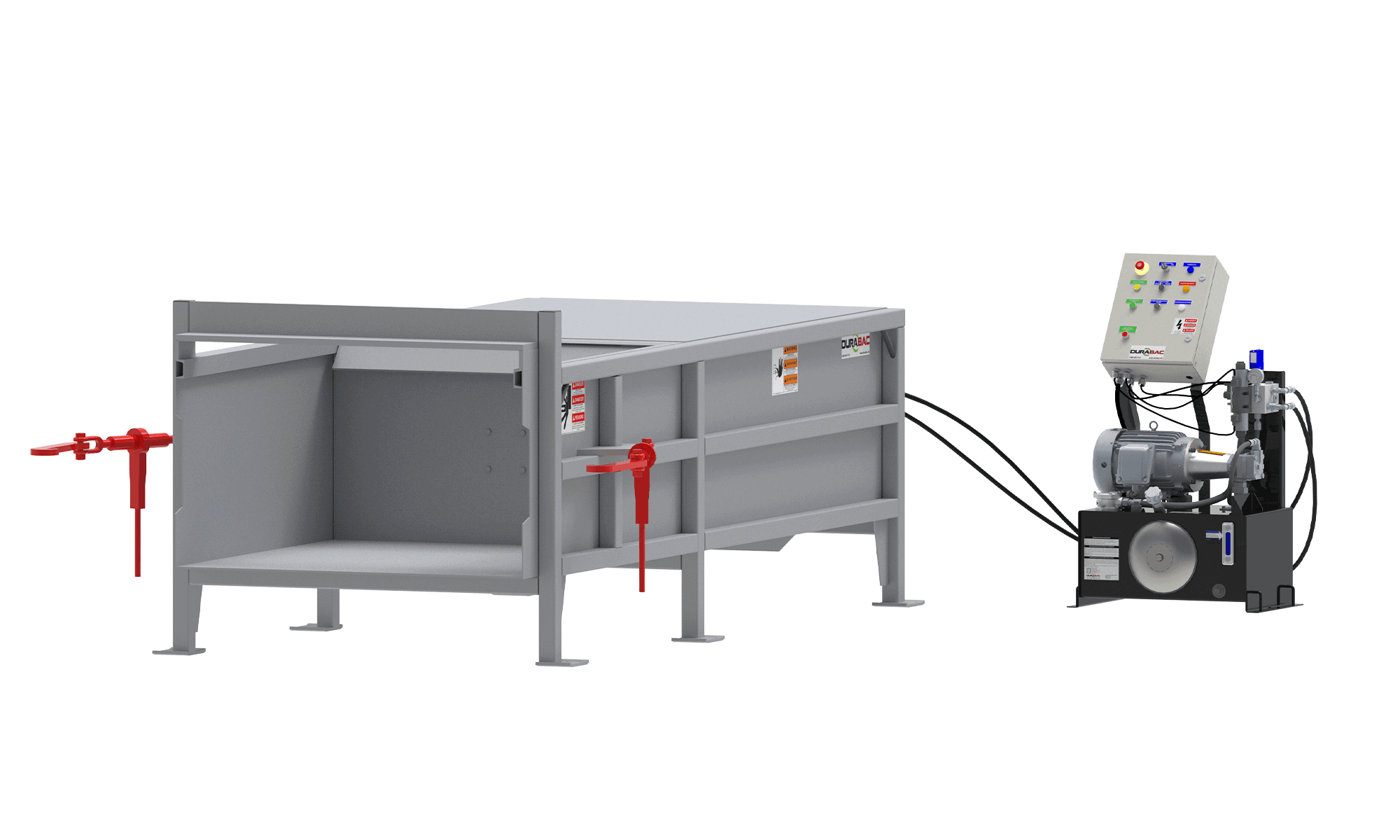

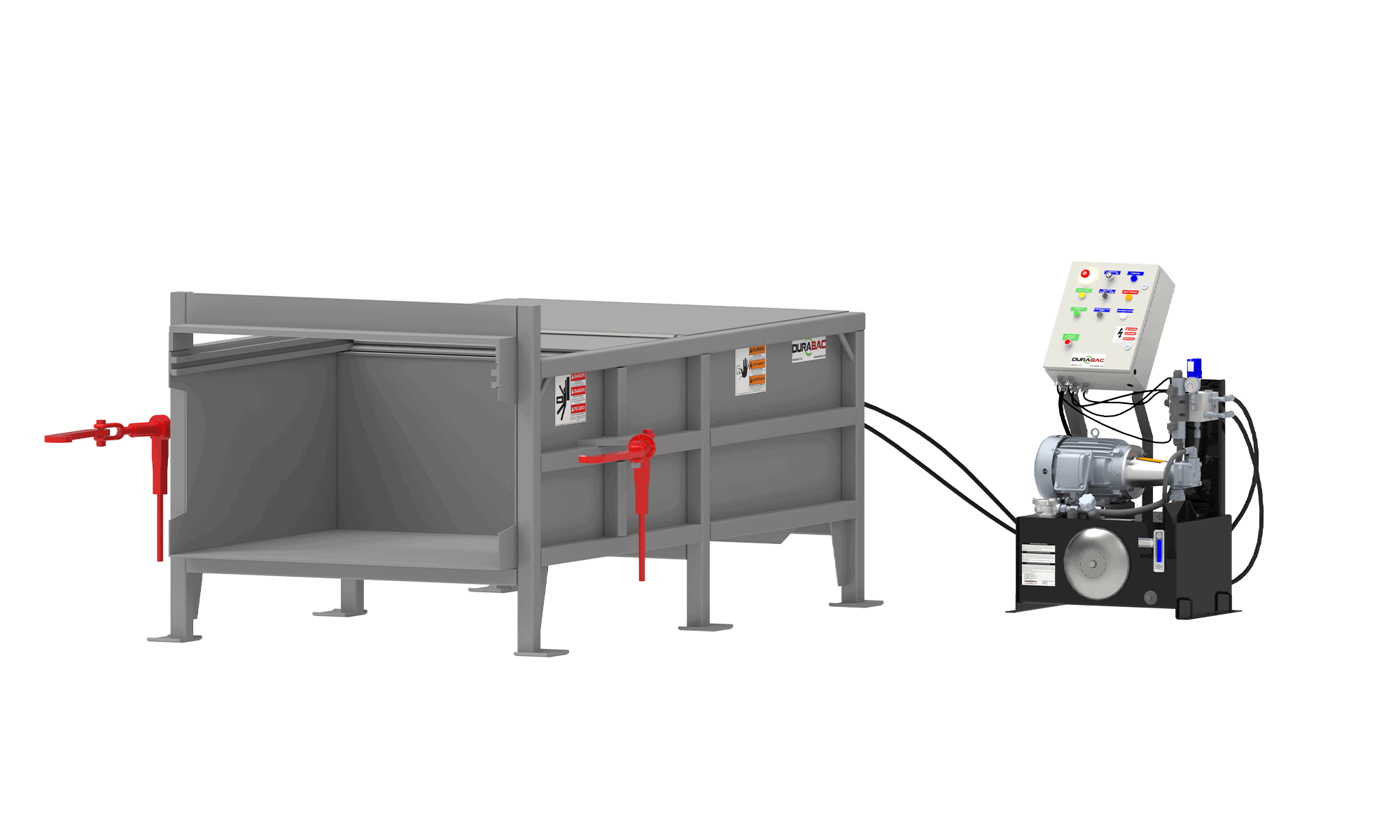

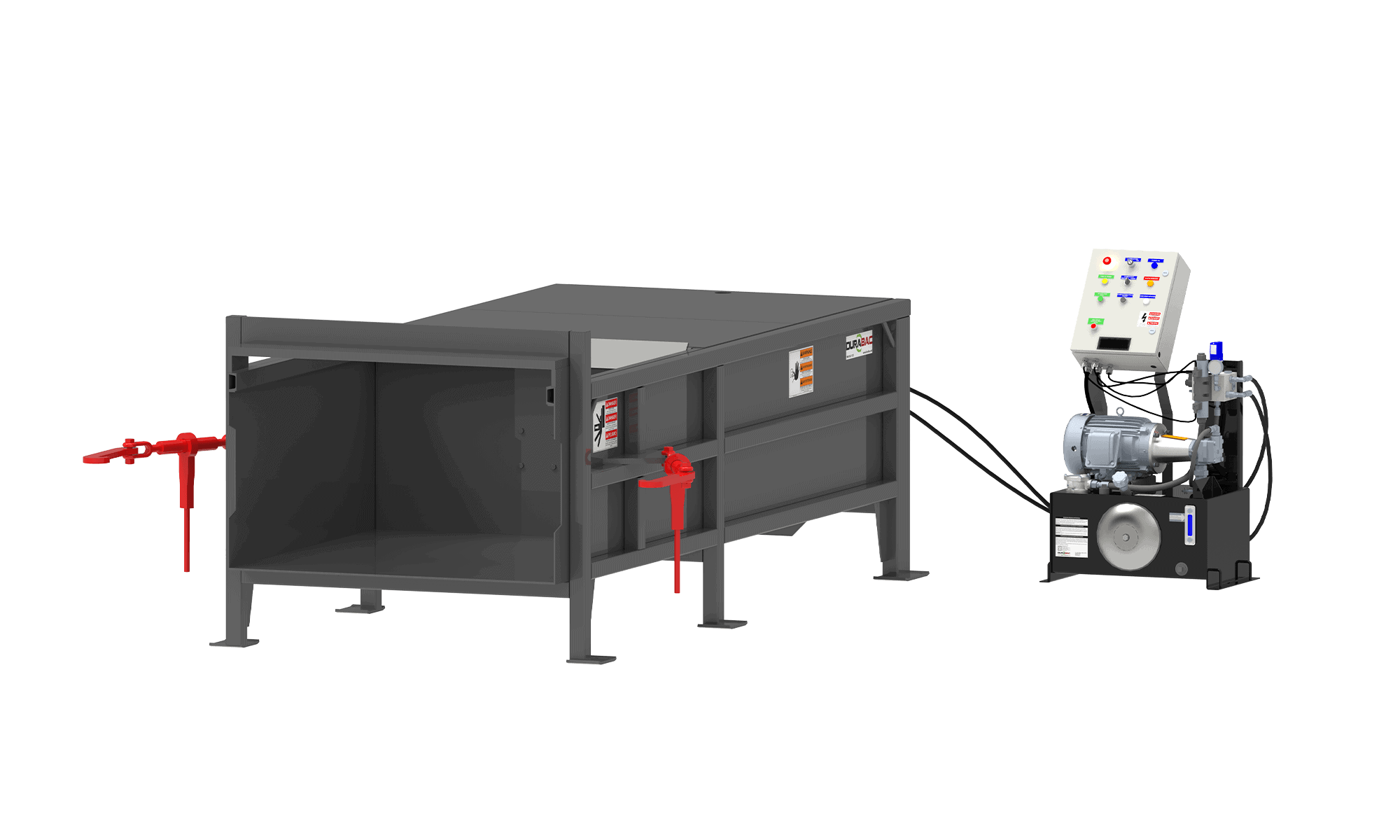

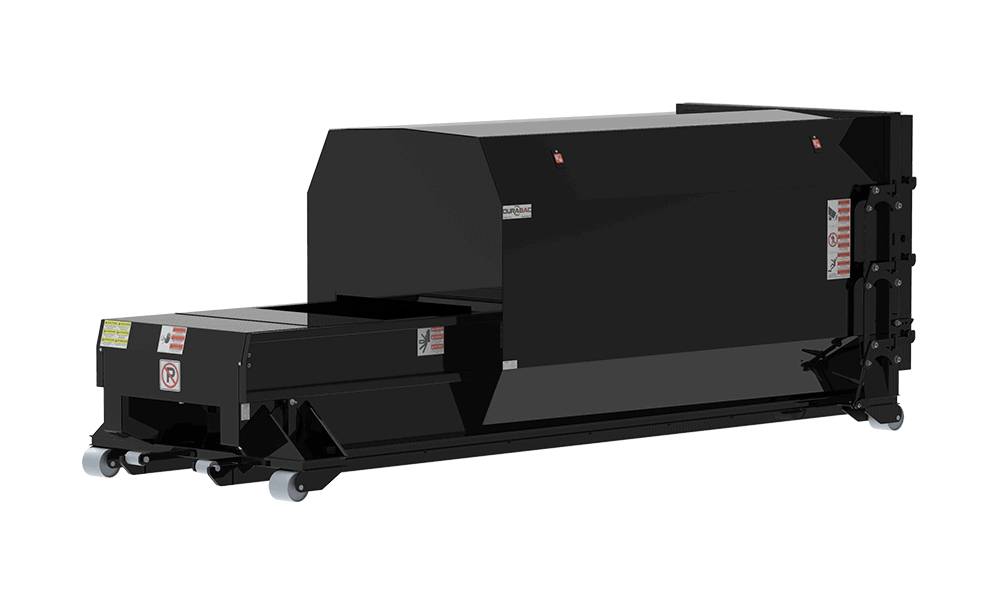

Discover our double-cylinder integrated compactor, an innovative and efficient solution for compacting materials with high liquid content. Designed with two crossed cylinders, this monobloc compactor stands out for its compact size, making it ideal for limited spaces. Its unique design combines mobility and robustness: the compaction box and the compaction unit are welded together, ensuring easy movement during the emptying of residues.

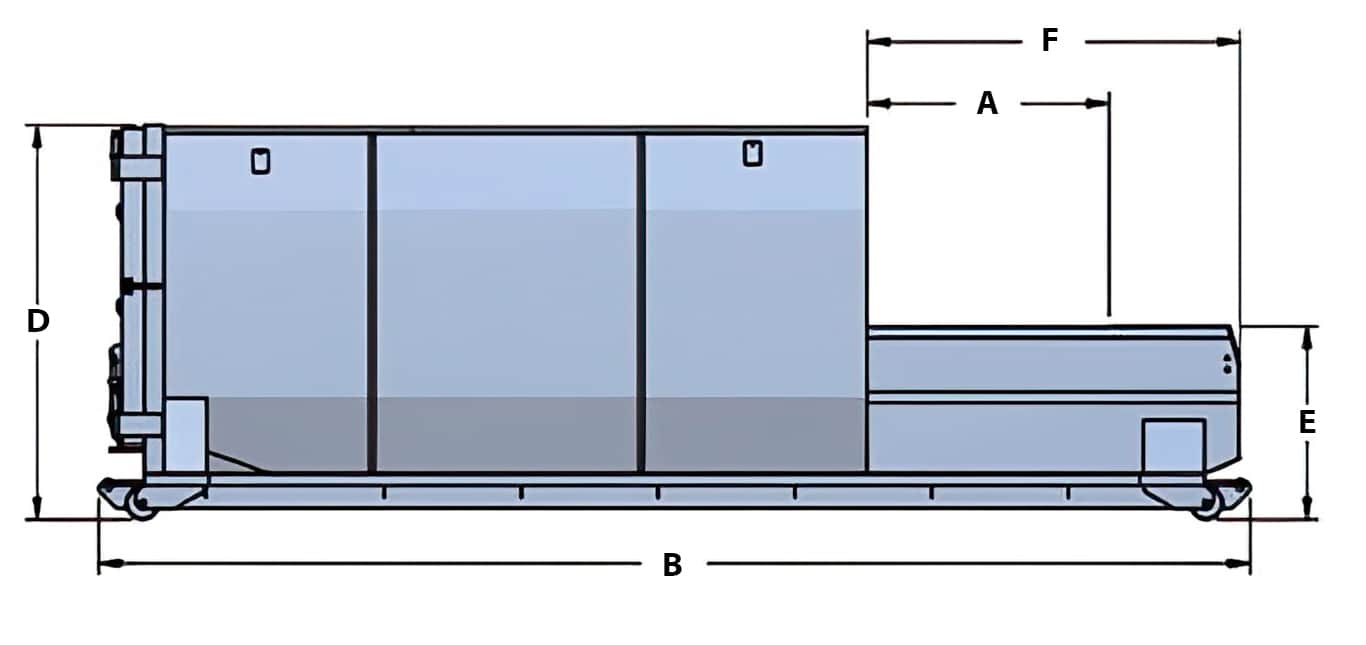

This compact model is available in various capacities – 28, 32, 34, and 36 cubic yards – with opening options of 42 or 60 inches, thus adapting to different compaction needs. Its sealed curved door optimizes material distribution, and its elevated floor ensures smooth and efficient ram movement. Additionally, the design of the cleaning panel and hydraulic couplings is intended for quick and effortless access.

Ideal for industries requiring efficient management of liquid waste, our 2-cylinder integrated compactor represents a practical and high-performance solution.

These compactors are used in restaurants, grocery markets, hospitals, hotels, shopping centers, and for any other applications where a clean, fast, and trouble-free compaction operation is required.