The Straight Deck Roll-Off Trailer, available in 2, 3, or 4 axle configurations, is engineered for optimal container transport. Featuring superior structural strength and constructed with a robust steel frame capable of handling 100,000 lb, this trailer offers a wide wheelbase between lifting cylinders, ensuring a stable and rigid lifting system. It adheres to the ANSI Z-245.60 2008 safety standard, making it a reliable and high-quality choice in the market.

Straight Deck Roll-Off Trailer

Straight Deck Roll-Off Trailer

Our "Straight Deck" Roll-Off Trailer, available in 2, 3, or 4 axle configurations, delivers superior container transport with its robust construction and compliance with the ANSI Z-245.60 2008 safety standard. A top-quality choice for uncompromised stability and rigidity!

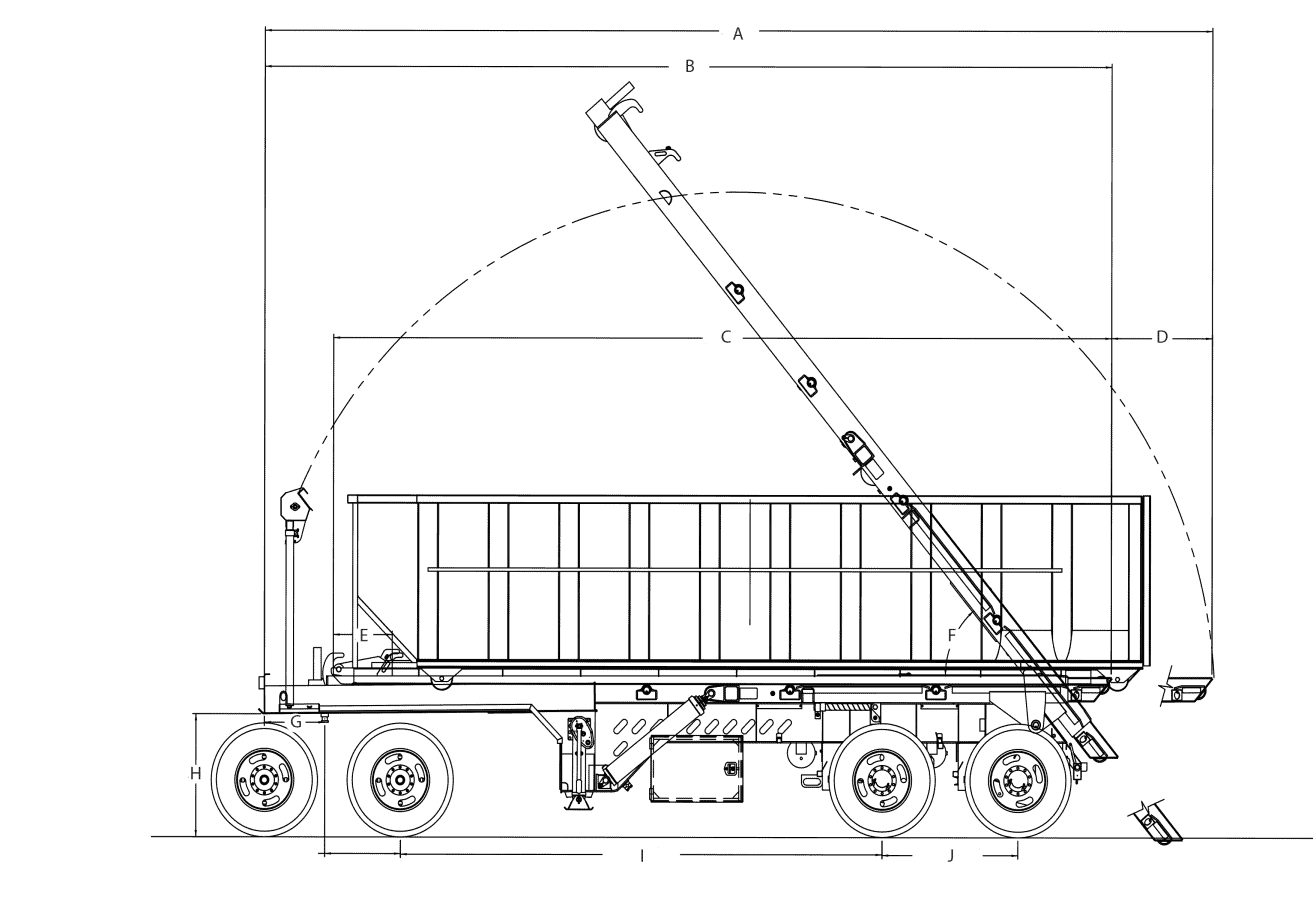

| Twin & Tri axles Trailer | CT-2AT | CT-38-3AT | CT-42-3AT | |

|---|---|---|---|---|

| A | Open tail length | 31′ | 38′ | 42′ |

| B | Closed tail lengh | 28′ | 34′ | |

| C | Front stop length at rear tail closed | 25′ | 31′ | |

| D | Telescopic tail | 40″ | 48″ | |

| E | 1st position removable stop | 60″ | 108″ | |

| F | Drain angle | 50° | 47° | |

| G | Position of the front of the trailer to the kingpin | 24″ | 60″ | |

| H | Fixing height for selette | 46″ | 24″ | |

| I | Rear axle position tractor truck to the kingpin | 30″ | 46″ | |

| J | Distances beteween rear axle truck to the 1st axle trailer | 191″ | 30″ | |

| K | Tandem axle spacing | 54″ | 197″ |

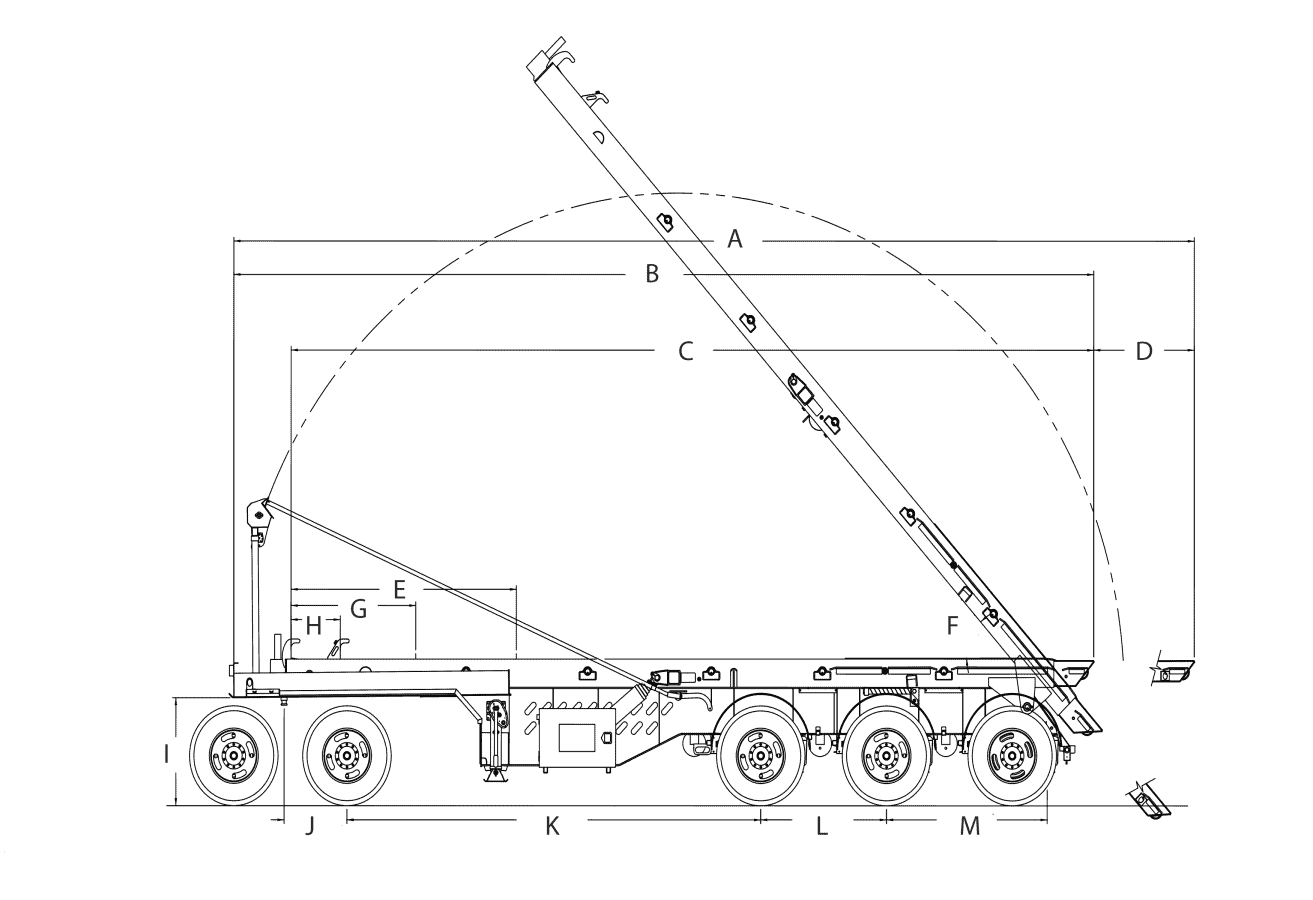

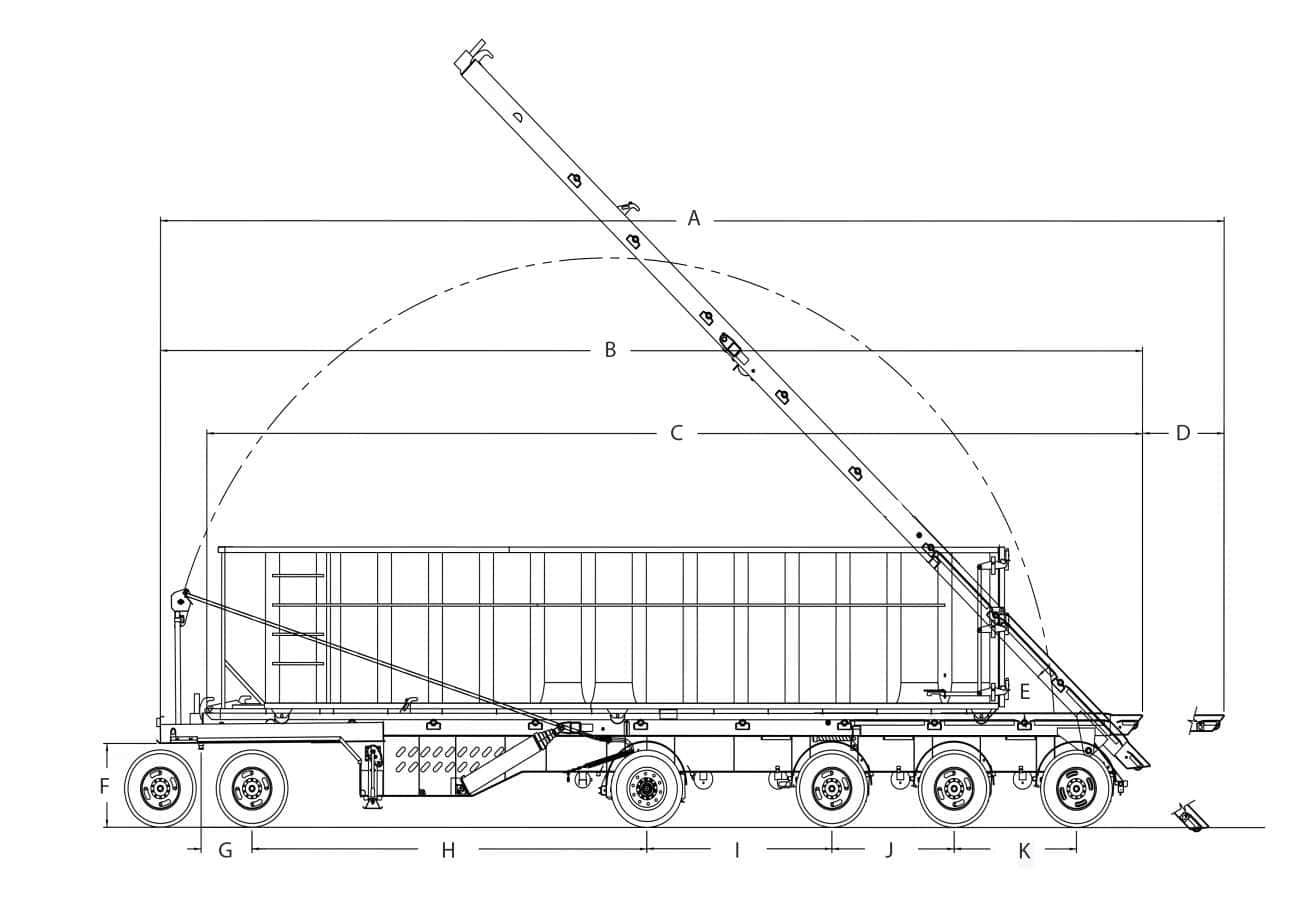

| Quad axles Trailer | CT-49-4AT | CT-52-4AT | |

|---|---|---|---|

| A | Open tail length | 49′ | 52′ |

| B | Closed tail lengh | 48′ | |

| C | Front stop length at rear tail closed | 45′ | |

| D | Telescopic tail | 48″ | |

| E | Drain angle | 44° | |

| F | Fixing height for selette | 46″ | |

| G | Rear axle position tractor truck to the kingpin | 30″ | |

| H | Distances beteween rear axle truck to the 1st axle trailer | 232″ | |

| I | Tandem axle spacing | 109″ | |

| J | Tandem axle spacing | 50″ | |

| K | Tandem axle spacing | 72″ | |

| L | Tandem axle spacing | 72″ |

* The parameters and dimensions given above are for guidance only. Actual dimensions may differ.

The system must be compliant with the AINSI Z-245.60 2008 safety standard, all safety labels must be in the working language, and the system must be compatible with U-type cable containers. It shall be manufactured with the highest quality standards, construction plans must be approved by an engineer member of an accredited board.

Lifting system:

- 80,000 lbs lifting capacity

- Available frame lengths:

- 2 et 3 axles : 24 ft. or custom, (Specifications for 24 ft., AC required 207 to 210)

- 4 axles : 52 ft.

- Frame lifting stingers : 4″ x 12″ x 3/8″ tubing (no subframe required)

- Mobile carrier is robust and bolted for easy maintenance, and the carrier includes Nylatron wear skids:

- 2 et 3 axles : 5/8″x 2 1/4″x 15″

- 4 axles : 1/2″x 4″x 20″

- 1″ (25.4 mm) hoist cable 6 x 26 of 106,000 lbs capacity with a “D-loop” bushing for increased flexibility and strength

- Winch sheaves:

- 12″ Sheave with 2″ shaft

- 8″ Sheave with 2″ shaft

- 10″ Sheave with 2″ shaft

- Side rollers with 4’’ mechanical tubing, 2 1/2″ shaft, aluminum bronze bushing with lubrication point and welded supports (at least 4 on each side), addition of 5/16 ” x 4″ flat bars between rollers to secure container movement

- Welded wear plates on rear part of stingers: 5/16″ x 3″ x 8′

- Ground roller between stingers: 6″ x 20″ HD. Bolted for easy maintenance

- Fixed front stopper (1 1/2″) approved by an engineer and welded in compliance with the CBW requirements

- Lightweight and safely removable stopper inserted into stingers for 20’or 22′ containers. Inserts must be seal welded in order to avoid water infiltration in the stingers’ core centre.

- 2″ hinge shaft with 6″ mechanical tubing hinges

- Galvanized corrugated steel fenders for tandem rear axles

- Steel safety tips that supports the frame during maintenance on the driver’s side

Hydraulic System:

- 10 micron filter installed in the tank with oil level and temperature indicator.

- Distribution by double-action VD12 hydraulic valve

- Lifting Cylinder (Side) 5″ (for 22′) and 6 1/2″ (for 24′ and 26′)

- Winch Cylinder: 7 1/2 “

- Control box inside the cab provides an ergonomic location and pneumatic controls on the hydraulic system

- External manual hydraulic controls with a 36 GPM valve

Electrical System:

- Electrical system approved by FMWSS / CMVSS L.E.D.

- All wiring is 100% waterproof

- Lighting arrangement on the bumper:

- 2 reversing lights activated during reverse

- 4 stop lights

- 1 plate light

- 3 stinger lights with MTC compliant side lights

- 1 tailgate rear light

Safety:

- All lights are LED

- Robust safety holders

- Fastener belt included in each container

Finish:

- Based on the selected options

Warranty:

- Structural manufacturing defect: 3 years

- Pumps, cylinders, or other hydraulic and electrical components: 2 years

- Rolling mechanical parts (Sheaves, cables, rolls, etc.): 1 year

- Hydraulic Hoses, Electrical Components: 1 year

- Steel flat plates between rollers for better support

- Additional winches and straps installed for container tie-down

- Additional container stopper holes

- Sainless steel fenders

- Hydraulic tarping system

- Air control on spool valve with quick coupler (to control from the cabin)

- Remote control

- Different paint colour

- Aluminum rims (polished on the outside)

- Tow hook welded to rear of trailer

- Steel or aluminium toolbox

- Air pressure gauge at front of trailer

- Air ride dump valve

- Disc brakes

- Available Top Skid and Inside-Outside rails

- Etc.

RELATED PRODUCTS

SUBSCRIBE TO OUR NEWSLETTER!

FOLLOW US!