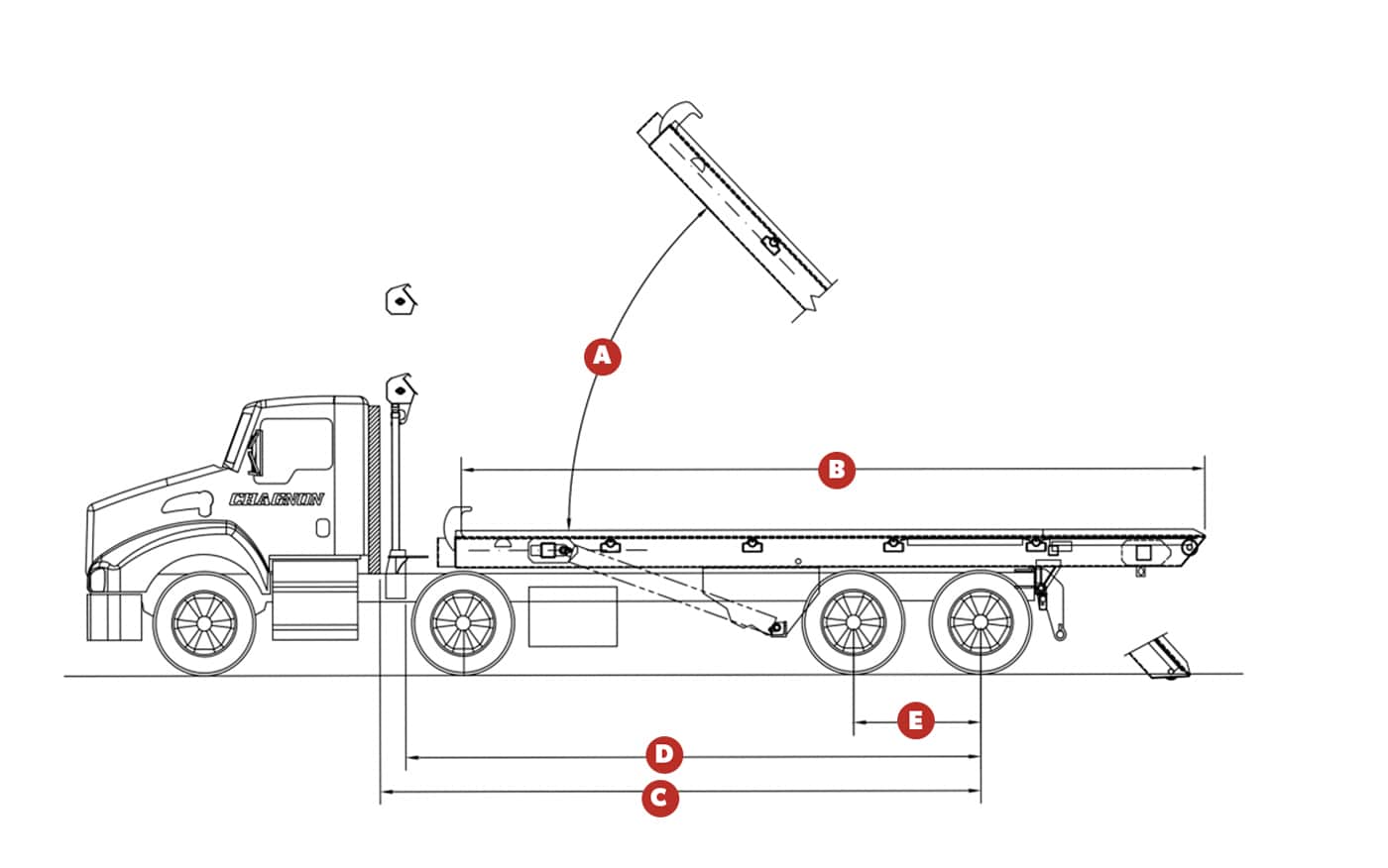

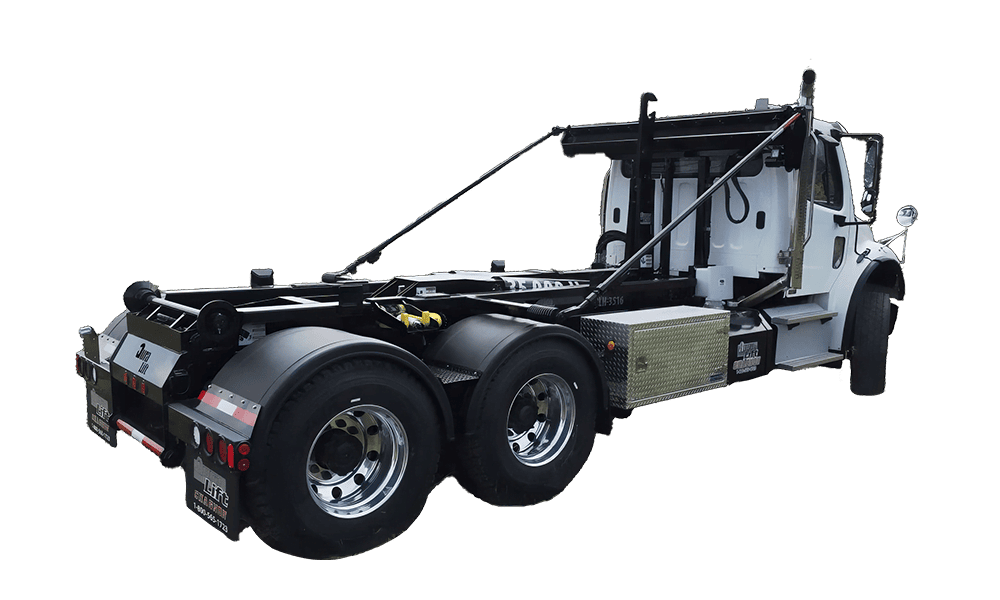

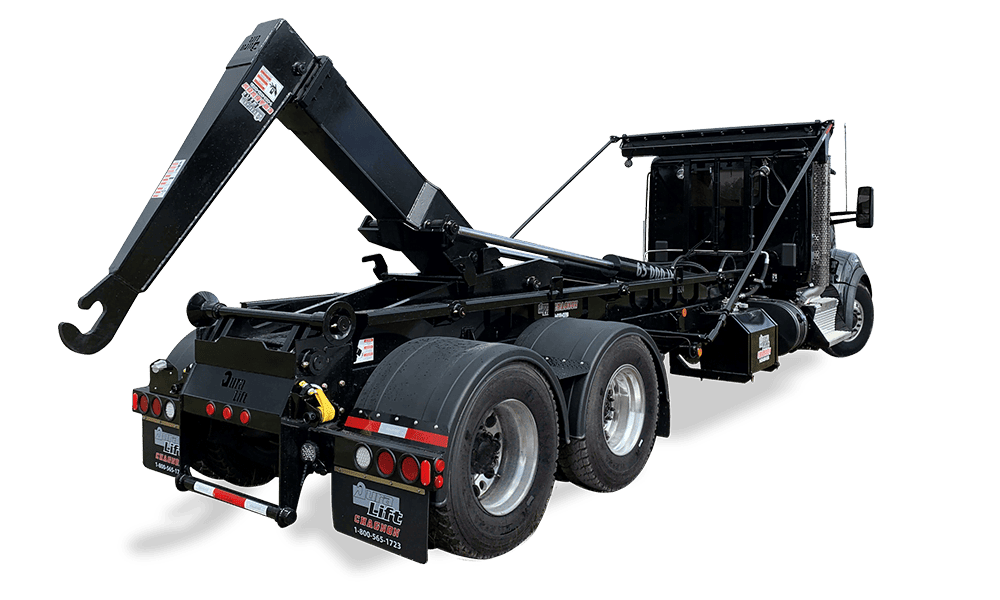

Our Inside/Outside Rail Roll-Off Hoist System, adaptable to both ANSI Z45.60-compliant outside rail and most inside rail containers, offers robust performance with options of 60,000 lb or 75,000 lb capacity and a 1″ hoist cable (6X26 – 106,000 lb.). Available in 22’, 24’, and 26’ lengths, it’s ideal for diverse settings, including commercial, municipal, and industrial use. User-friendly and low-maintenance, it exceeds industry standards (ANSI Z245.1, CSA W47.1, FMVSS/CMVSS, WASTEC, etc.), ensuring superior assembly quality.

* The parameters and dimensions given above are for guidance only. Actual dimensions may differ.