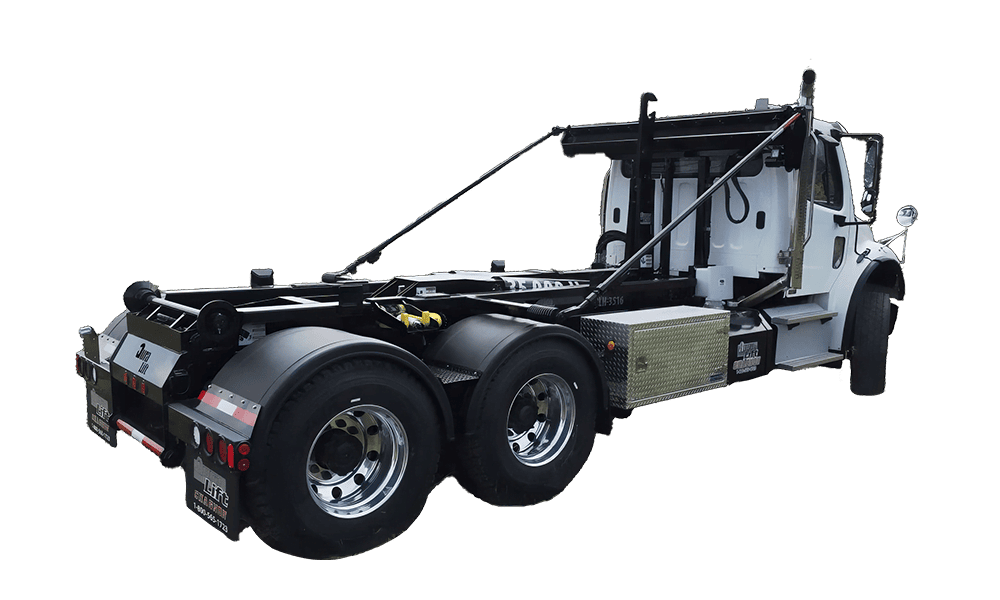

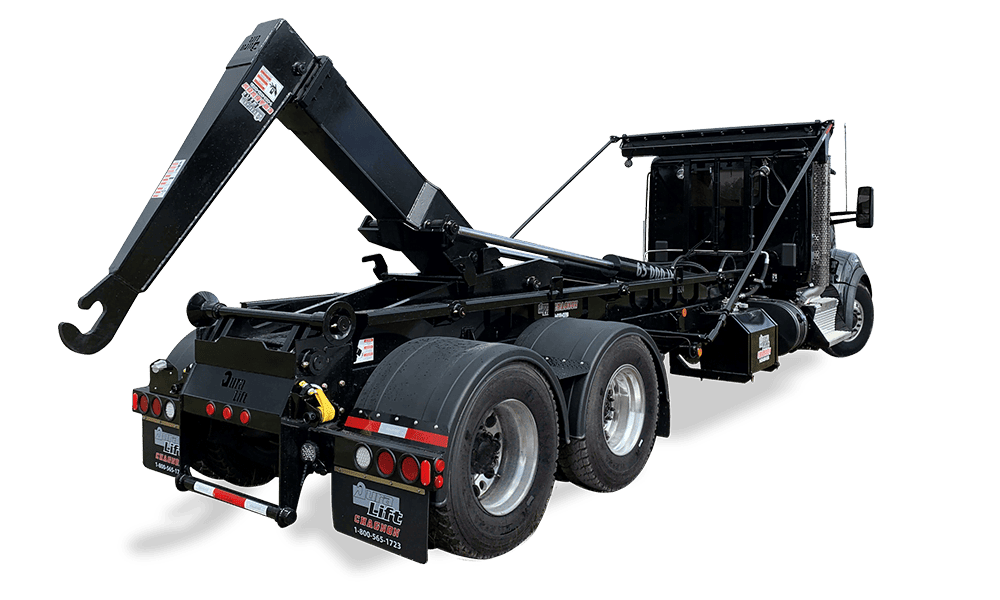

Our Top skid roll-off system is suitable for the most demanding jobs and compatible with most varieties of top skid or slide on outside rails containers (without lead in rollers).

Offers robust performance with options of 60,000 lb or 75,000 lb capacity and a 1″ hoist cable (6X26 – 106,000 lb.), it is designed for sturdiness and superior quality.

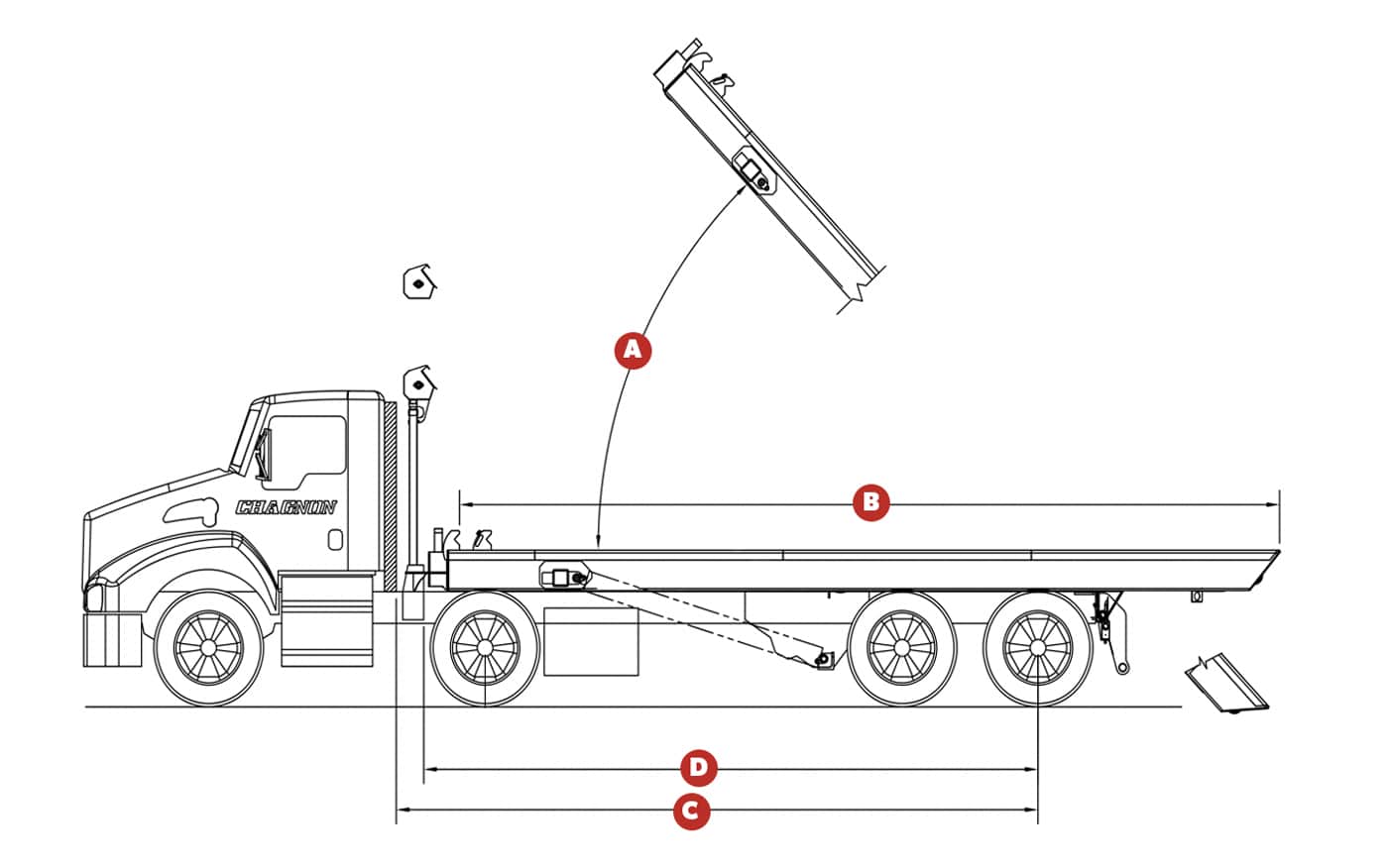

Available in 22’, 24’ and 26’ lengths, it is ideal for commercial, municipal and industrial use. Easy to operate and maintain, its assembly quality exceeds all industry standards (ANSI Z245.1, CSA W47.1, FMVSS/CMVSS, WASTEC, etc.).